An innovative Coriolis sensor exploits mechanical effects utilizing inertial variations for efficient mass evaluation. As the medium travels through twisted pipes, centripetal effects yield deviations in fluid pathway, proportional to volumetric rates, permitting accurate flow analysis. Esteemed for technological versatility, capable of assessing diverse fluid types with negligible head drop.

- Merits of Coriolis Flow Meters:

- Remarkable precision levels:

- Flexible flow type compatibility:

- Combined mass and viscosity metrics:

Understanding Principles of Coriolis Devices

Innovative Coriolis meters act as effective tools employed to determine accurately within tubing. Applying inertial deflection principles, the instrument detects fluid displacement induced by rotation. Within dynamic tubing sections, liquid course alters laterally, dictated by fluid velocity. Detectors register displacement, altering deflections to flow information proportional to flow magnitude.

- Applications of Coriolis flowmeters include:

- Production control in chemical sectors

- Pharmaceutical manufacturing

- Sewage management

Deciding Optimal Flow Measurement Tools

Coriolis meters excel in providing fine resolution for fluid flow analysis. Yet, with varieties of available models, selecting the best fit for applications may be complex. Key considerations when evaluating your Coriolis flow meter include: * **Characteristics of the fluid:** The fluid tested impacts makeup and performance. * **Flow capacity range:** Meters execute within distinct flow limits. Guarantee your needs are met. * **Accuracy standards:** Different use cases expect diverse precision levels. Determine these to narrow down models. * **Operational environment:** Factors such as temperature, pressure, and fluid viscosity influence meter outcomes. * **System compatibility:** Assess integration and attachment with existing infrastructure.Advantages Offered by Contemporary Coriolis Instruments

Innovative Coriolis technologies provide a ample selection of positive features for industrial needs. Initially, these meters offer leading precision, facilitating precise throughput analysis. Further, Coriolis meters provide simultaneous mass and specific gravity tracking in one device, making them notably suited for mission-critical measurement. Furthermore, their strength enables operation in severe backgrounds.

- Hence, these devices see pervasive use in markets like oil and gas, chemicals, food and beverage sectors, and pharmaceuticals.

State-of-the-Art Calibration Practices

Rigorous factory conditions prioritize Coriolis flowmeter performance. Ensuring dependable, repeatable results demands innovative calibration methods. These exceed basic protocols by integrating expert tools and detailed analysis.

Calibrators support precise flowmeter tuning. By comparing meter outputs with known benchmarks, technicians detect divergences and apply corrections.

- Multi-point calibration, assessing various flow rates, yields complete performance profiling across meter ranges.

- Advanced software assists data management and visualization, enabling calibration curve creation.

Consistent use of advanced calibration ensures optimal meter accuracy, driving efficiency gains across industries.

Diagnosing Standard Coriolis Errors

Coriolis meters provide trusted accuracy and adaptability yet face occasional concerns. Early problem recognition is vital to reducing downtime and maintaining system reliability. Typical complications involve data fluctuation, often caused by improper setup, dirty sensing components, or flow disturbances. Sensor jitter may result from changing fluid properties, mechanical vibrations, or electromagnetic disturbances. Effective problem-solving requires thorough examination of conditions, sensor outputs, and operational logs.

- Consistent monitoring for damage or contamination applies.

- Recalibration as prescribed maintains accuracy.

- Tracking readings aids early detection.

- Optimal arrangement helps reduce interference.

Using proven techniques fixes common Coriolis flowmeter challenges, ensuring reliable fluid monitoring and operational consistency.

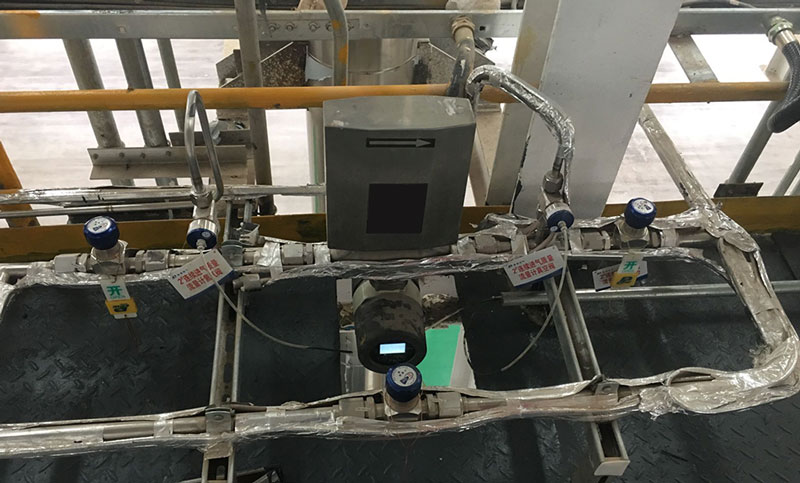

Deploying Coriolis Flow Technology in Industrial Control

Devices supply robust mass flow assessment within industrial applications. Utilizing the Coriolis effect triggered by fluid passage inside vibrating tubes, fluctuations in tube motions correspond to fluid liquid quantity. This factor enables high-fidelity quantification of liquid motions even in rigorous environments.

They fit perfectly a multifaceted range of uses, including water treatment. Their resilience makes them recommended for intensive sites, and their electronic signaling enables network compatibility with process controls.

Superior Flow Measurement through Coriolis Sensors

Coriolis sensors deliver consistent medidor de flujo coriolis precision across wide applications. They employ rotational physics to quantify mass flow, yielding highly reliable data under demanding flow regimes. In comparison with alternative flow technologies, Coriolis sensors provide instant readings, facilitating detailed monitoring. Their dual ability to measure mass flow and density makes them ideal for multivariate flow assessments. Furthermore, Coriolis sensors exhibit endurance, thriving in severe operating locations. This combination of accuracy qualifies Coriolis sensors as a dominant choice for demanding flow measurement situations.Industrial Metering in Oil & Gas Fields

Coriolis flowmeters have validated themselves as accurate tools in the oil and gas field. Their capacity to simultaneously measure mass flow and medium concentration renders them multi-purpose for many operational tasks. In upstream workflows, Coriolis meters facilitate monitoring energy liquids in refineries. They also fulfill major roles in system management and guarantee trustworthy metering for financial settlements.The Role of Coriolis Flowmeters in Water Management Systems

Flow measurement devices enable effective control for precise assessment in water management contexts. Utilizing inertia principles, they observe flow alteration through bent tubes. This exact data enables real-time liquid tracking, key for raising system capability.

- Operations of Coriolis flowmeters in water systems span broad utilities, such as: distributing water to homes and industries, observing water intake for irrigation and electricity generation, and overseeing water flow in cleaning plants.

- Positive Aspects for Coriolis flowmeters in this area consist of: superior precision, broad range across flow profiles, and minimal maintenance requirements.

Boosting Measurement Accuracy via Coriolis Systems

Coriolis flowmeters have shown themselves as trusted solutions for analyzing media. These methods apply the Coriolis effect to determine both mass flow and fluid density. Using Coriolis technology can boost measurement accuracy, reduce operating expenses, and present insightful data about process characteristics. Their versatility enables use in a expansive range of applications such as manufacturing.