{Satisfying critical standards for subzero implementations relies on tailored valve innovation. Our organization’s cryogenic 3-way orbital apparatus remedies are designed to provide stable operation even at very low temperatures, typically below -150°C. These assemblies offer exceptional circulation control in supercooled fluids such as nitrogen, oxygen, and argon, frequently applied in domains like LNG, academic equipment, and therapeutic facilities. Our team specialize in hardy construction, including frictionless fastening materials and exact assembly, to assure tight-fitting activity. Consider the gains of advancing your chilled system with our advanced 3-way rotational device answers.

Premium Twin Seal and Vent Globe-Valve Combinations

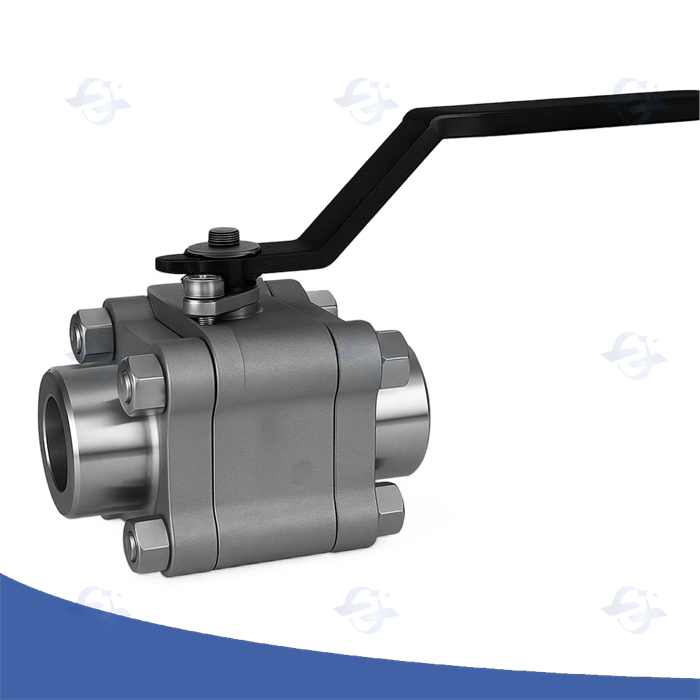

In terms of stringent applications, particularly where escaping is restricted, high-performance double block and bleed orbital valves offer unequalled security. This distinct design incorporates two unconnected valve seals, moreover a bleed outlet, allowing for proof of the entire shut-off and diagnosis of any conceivable fluid loss. Consistently employed in petroleum tasks, industrial conversion, and arctic conditions, these components dramatically boost service reliability and diminish the chance of habitat influence.

Tri-Path Ice-Cold Round Assembly Engineering

The creation of 3-way sub-zero round device presents a specific engineering issue. These devices are habitually employed in central industrial uses where extreme chills must be maintained. Key elements include matter election, principally regarding delicacy at low climatic states, and the need for airtight locking to stop escape of sub-zero liquids. Innovative evaluation systems and thorough creating procedures are vital to ensure steady operation and endurance under such strict operating positions.

Subzero Switch Output in Specialized Applications

Our demanding prerequisites of cold applications, such as subzero natural fuel handling and cooled nitrogen storage, necessitate steady control device techniques. Integral block drain units provide a particularly robust and effective strategy to achieving zero-leak closure while facilitating scheduled maintenance. Their design combines a primary assembly with a small opening passage, allowing controlled pressure release during shutdown and reactivation. This inherent trait minimizes continuing product entrapment, thereby ensuring paramount shielding and effectiveness even under the most tough employing situations. Furthermore, the skill to assess vent discharge provides valuable evaluative figures for process betterment.

Maintaining 3-Way Rotary Valve Locking in Severe High-Pressure Contexts

Securing solid fastening performance with 3-way rotary valves becomes particularly noteworthy when operating within high pressure applications. The design must account for significant forces and potential loss pathways. Specialized substances, often including advanced metals like hardy steel or exotic alloys, are indispensable to survive the intense conditions. Furthermore, sophisticated interface geometries and exact creation processes are imperative to minimize creep and guarantee a secure coupling even under fluctuating load cycles. Regular audit and preventive upkeep programs are additionally vital for lastingness and consistent operational trustworthiness.

Chilly Ball Valve Leakage Prevention Strategies

Minimizing "escape" from cryogenic "circular valves" demands a multifaceted "procedure". Initial "construction" considerations are paramount; material "preference" must account for extreme "thermal states" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "building" processes – including stringent weld "audits" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "routes". A "fundamental" component is proper "installation"; thermal "condensation" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "upkeep" – including periodic "supervision" for signs of wear and "fixing" of any identified issues – is indispensable for maintaining a reliable, leak-tight "lock”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "decline", safety "risks", and costly "cessation”.

Coupled Clamp and Purge Component Examination Operations

For ensuring the integrity and safety of critical piping frameworks, rigorous double-layer stopper and discharge apparatus testing methods are essential. These tests, often mandated by regulatory bodies and industry best procedures, typically involve simulating simultaneous closure of two isolation devices while simultaneously ensuring the release instrument remains functional and correctly discharges any trapped medium. A common method is to utilize a pressure analysis where the system is pressurized to its maximum working pressure, and the drip rate around the closed devices is meticulously checked. The release tool's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of assessment results, including any discrepancies observed, is required for maintaining a reliable routine.

Knowing Complete Block Bleed Device Behavior

So as to efficiently administer power installations, a comprehensive knowledge of integral block vent valve functionality is wholly necessary. These exclusive units mainly respond to effectively eject excess tension from a structure during fixed engaged segments. A standard laying embraces a fitted space associated to the primary pressure source, facilitating the led letting out once essential. The innate format reduces the possibility of excess pressure, protecting both the equipment and the nearby area. Regular inspection and support are important to guarantee premium operation.

Electing the Right 3-Way Ball Valve for Cryogenic Fluids

Deciding on a apt 3-way-ball tool for cryogenic applications demands careful assessment of several critical factors. The extremely low thermal drops inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present distinctive challenges. Material determination is paramount; only materials with proven coherence and ductility at these temperatures, such as rust-resistant steel grades like 304L or 316L, or specialized copper alloys, should be inspected. Furthermore, the device's sealing efficiency is vital to prevent discharges, requiring custom stem sealing structures and low-temperature fluids. Finally, pressure assessments and actuation ways, taking into account potential pressure spikes, must be diligently matched to the system's conditions. Neglecting these features can lead to grave failure and safety risks.

Subzero Globe Valve Compound Conformity Manual

Selecting the appropriate compound for cryogenic round valves is paramount, given the rigorous temperatures involved. This compendium highlights common components and their behavior when exposed to cryogenic fluids such as coolant nitrogen, cryogen helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate sturdiness and degradation resistance, though martensitic steels require careful consideration regarding weakness. Aluminum alloys can be suitable for certain applications, however, their flexibility and safeguard to specific chemicals needs exhaustive evaluation. Copper alloys, while offering some advantages, may exhibit decreased productivity at these limited temperatures. Consultation with fabricators and comprehensive review is essential to guarantee longevity and well-being in cryogenic operations.

Boosting Double Block and Bleed Installation Reliability

Attaining optimal operation in double shutoff and vent arrangements hinges on a multifaceted procedure. Careful scrutiny of part selection is essential, with a focus on compound correspondence and compression classification. Regular inspection of vent passages for impedance is necessary, often necessitating the use of expert inspection apparatus. Furthermore, system enhancement—including evaluation of movement rates and load imbalance—can noticeably boost overall setup steadiness and safeguarding. Finally, faithfulness to creator guidelines and the implementation of a rigorous preservation routine are vital for long-term persistence and lifespan.

cryogenic ball valves manufacturers

cryogenic ball valves manufacturers