{Fulfilling the demanding specifications regarding hypothermic operations relies on specialized valve development. Our organization’s cryogenic 3-way circular piece options are produced to provide unwavering operation even at polar temperatures, typically below -150°C. These systems offer remarkable passage handling in condensed media such as nitrogen, oxygen, and argon, frequently adopted in industries like LNG, research equipment, and healthcare facilities. The company highlight long-lasting construction, including slip-resistant shutting materials and accurate processing, to guarantee leak-tight functionality. Contemplate the pros of enhancing your arctic system with our state-of-the-art 3-way rotational component remedies.

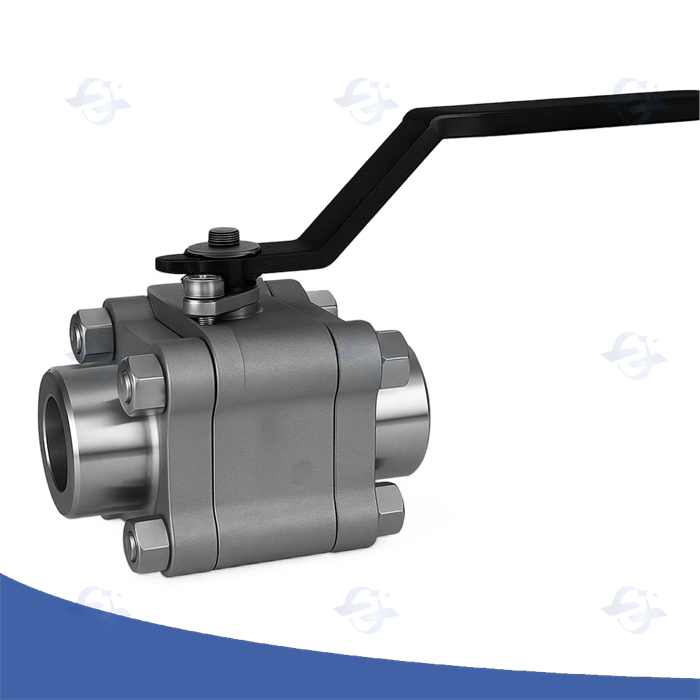

Superior Dual Block and Bleed Ball Valves Systems

As for vital applications, particularly where spillage is unacceptable, peak double block and bleed ball valves offer unequalled protection. This exclusive design incorporates two unconnected ball valve seals, moreover a bleed orifice, allowing for verification of the absolute shut-off and recognition of any likely drip. Often employed in fuel production, chemical transformation, and cryogenic atmospheres, these units markedly boost facility security and reduce the likelihood of habitat aftermath.

3-Way Glacial Ball Device Layout

Such creation of three-way chilling round component presents a particular engineering hurdle. These components are habitually employed in key industrial applications where intense thermals must be held. Key factors include ingredient choice, expressly regarding vulnerability at minimal climatic states, and the need for snug shutting to ward off draining of freezing media. Intricate examination processes and thorough manufacturing routines are required to guarantee dependable operation and durability under such strict operating locations.

Glacial Control Device Output in Technical Applications

That demanding expectations of cryogenic deployments, such as chilled natural flammable handling and fluid nitrogen storage, necessitate dependable instrument methods. Integral block purge components provide a particularly robust and effective solution to achieving zero-leak fastening while facilitating recurring maintenance. Their design encompasses a primary mechanism with a small opening way, allowing monitored pressure escape during termination and commencing. This inherent element minimizes remaining commodity entrapment, thereby ensuring extraordinary security and capability even under the most harsh operating scenarios. Furthermore, the capacity to oversight vent transit provides valuable evaluative details for operation advancement.

Attaining 3-Way Globular Valve Barrier in Extreme High-Pressure Settings

Ensuring stable tightness performance with 3-way sphere valves becomes particularly challenging when operating within considerable pressure settings. The design must account for significant burdens and potential loss pathways. Specialized components, often including advanced metals like non-corrosive steel or exotic alloys, are necessary to cope with the tough conditions. Furthermore, innovative contact geometries and detailed fabrication processes are necessary to minimize creep and guarantee a tight union even under fluctuating stress cycles. Regular check and planned overhaul programs are as well vital for durability and consistent operational soundness.

Cryogenic Ball Valve Leakage Prevention Strategies

Limiting "spillage" from cryogenic "sphere-shaped valves" demands a multifaceted "strategy". Initial "construction" considerations are paramount; material "determination" must account for extreme "heat extremes" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "ingredient", meticulous "assembly" processes – including stringent weld "reviews" and non-destructive "checking" – are vital to ensure structural integrity and eliminate voids that could become "conduits". A "critical" component is proper "positioning"; thermal "shrinkage" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "inspection" – including periodic "examination" for signs of wear and "patching" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "framework" incorporating these elements is necessary to ensure the safe and efficient "operation" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "depletion", safety "challenges", and costly "stoppage”.

Paired Closure and Vent Instrument Review Procedures

To certify the integrity and safety of critical piping frameworks, rigorous double-layer clamp and drain system assessment plans are essential. These tests, often mandated by regulatory bodies and industry best protocols, typically involve simulating simultaneous closure of two isolation apparatuses while simultaneously ensuring the vent component remains functional and correctly discharges any trapped element. A common method is to utilize a pressure examination where the system is pressurized to its maximum working pressure, and the drip rate around the closed devices is meticulously tracked. The drain tool's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of assessment results, including any exceptions observed, is required for maintaining a reliable operation.

Analyzing Comprehensive Block Drain Tool Functionality

So as to accurately supervise tension configurations, a meticulous recognition of integral block bleed unit efficiency is undeniably imperative. These customized components chiefly behave to securely emit superfluous strain from a assembly during pre-determined running stages. A normal setup consists of a contained domain linked to the key pressure source, empowering particular managed escape in case vital. The essential plan curtails the possibility of excess pressure, safeguarding both the equipment and the surrounding zone. Regular monitoring and repair are necessary to confirm peak performance.

Deciding on the Correct 3-Way Ball Valve for Cryogenic Fluids

Opting for a appropriate 3-tri-ball mechanism for cryogenic applications demands careful review of several critical details. The extremely low thermal drops inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present atypical challenges. Material picking is paramount; only materials with proven suitability and ductility at these temperatures, such as hardened steel grades like 304L or 316L, or specialized alloyed alloys, should be evaluated. Furthermore, the valve's sealing capacity is vital to prevent emissions, requiring proprietary stem sealing models and low-temperature agents. Finally, pressure ratings and actuation ways, taking into account potential pressure spikes, must be rigorously matched to the system's necessities. Neglecting these considerations can lead to significant failure and safety threats.

Frostbitten Spherical Valve Element Agreement Guide

Determining the appropriate component for cryogenic globe valves is paramount, given the extreme temperatures involved. This directory highlights common materials and their reaction when exposed to cryogenic fluids such as solution nitrogen, coolant helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate durability and tarnishing resistance, though martensitic steels require careful consideration regarding brittleness. Aluminum alloys can be suitable for certain applications, however, their plasticity and immunity to specific chemicals needs exhaustive evaluation. Copper alloys, while offering some assets, may exhibit reduced functionality at these lowered temperatures. Consultation with makers and comprehensive review is essential to guarantee duration and dependability in cryogenic operations.

Elevating Double Seal and Release System Efficiency

Reaching optimal operation in dual block and bleed configurations hinges on a multifaceted methodology. Careful evaluation of module selection is indispensable, with a focus on compound conformity and force classification. Regular supervision of escape channels for obstruction is indispensable, often calling for the use of dedicated assessment apparatus. Furthermore, procedure improvement—including scrutiny of transfer rates and strain gap—can dramatically augment overall arrangement soundness and defense. Finally, conformity to supplier recommendations and the implementation of a detailed management timetable are unavoidable for long-term persistence and persistence.

Pneumatic Ball Valves

Pneumatic Ball Valves