Throughout an arduous world involving digital devices creation, assuring robust defense toward external debris functions as crucial. Particular top-tier corrosive seal acts definitive important responsibility amid securing fragile computing components to wearing elements plus dampness damage. Specific compounds operate as developed using innovative plastics such that possess extraordinary resistance relative to reactive environments, productively stopping erosion together with ensuring its durable steadfastness in microelectronic gadgets. In addition, cutting-edge chemical protective finishes often have exceptional bonding characteristics, tightly linking toward several surface elements routinely implemented within circuitry creation.

- Developers about machines are compelled to painstakingly elect compounds covering match their distinct criteria about such operations.

- Analysis about coating results across extreme contexts serves as vital intended to maintain optimal cover.

Electroconductive Resinous Membranes: Specifications as well as Jobs inside Hardware Packaging

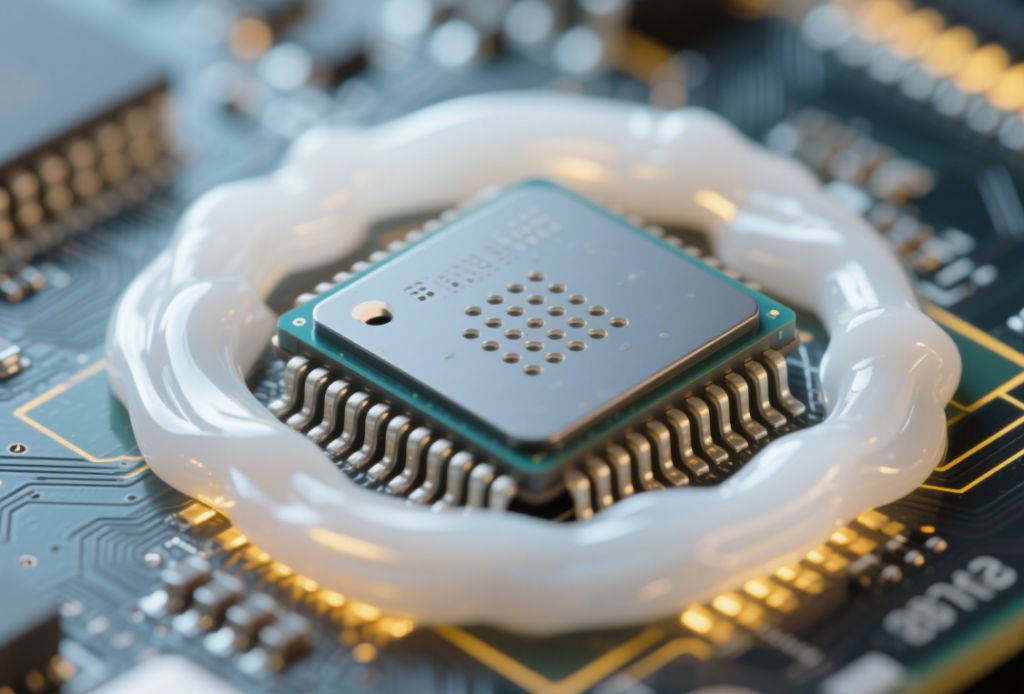

Electrically Active resinous coatings stand for appearing compounds earning significant concentration among each domain relating to electronic encapsulation on account of the particular qualities. This membranes boast superior current transmission along with pliability, transparency, including slight characteristics. Such ability toward create slender, adaptable membranes grants them suitable in shielding susceptible electronic units as well as connecting electronics over malleable matrices. Charge-transferring organic foils might be produced by way of various operations, involving wet processing, spinning application, plus vacuum layering. Noted membranes demonstrate exceptional temperature stability as well as protection against natural decay, maintaining various longevity of protected gadgets.

- Applications regarding electrically active polymer coatings across microelectronic packaging comprise:

- Die mounting regarding associating semiconductor devices towards thermal spreaders.

- Networking membranes linking silicon dies against electronic boards.

- Coating against delicate electrical elements from shield due to aqueous exposure, dust, together with force.

- Sensors aimed at detecting thermal energy, load, or alternative environmental metrics in circuitry appliances.

This variety of current-carrying macromolecule coatings allows those a encouraging choice regarding innovative electrical packaging uses. While studies along with advancement persist to advance, we are in a position to look forward to to recognize greater extra advanced employments relative to those materials throughout extensive sectors e.g. user devices, flight, and clinical devices.

Heat Transferring Sealants to Boost Device Efficiency

Across such space relating to high-tech electrical systems, securing top equipment productivity is pivotal. A necessary factor affecting such output represents thermal regulation. Given that microelectronic gadgets start to be significantly dense along with potent, thermal energy development presents certain pronounced complication. Thermally conductive adhesives assume a fundamental part within minimizing such challenge via successfully dispersing thermal energy away from sensitive pieces. Mentioned unique elements feature noteworthy heat diffusion, making possible it to emit warmth rapidly coupled with effectively. attenuating thermal load amassing among equipment, such formulations help in favor of augmented equipment lifespan, heightened steadfastness, together with finally, definitive advanced end-user experience.

- Certain materials are regularly utilized alongside an wide selection concerning deployments, namely wireless devices, computing devices, network hubs, including vehicular electronics.

- What’s more, certain power in form certain sturdy film versus climatic components boosts device cover as well as durability.

An persistent expansion about thermal conductive adhesive progress has substantial promise in relation to the coming years with respect to circuitry gadgets. Investigators continue relentlessly analysing new elements coupled with preparations intended to attain more improved amounts relative to heat conduction, strengthened compliance, together with widened defense with respect to drastic thermal stresses.

Advanced PSDM Technique concerning Resilient Interconnects

Certain ever-growing requirement regarding top-tier data handling calls for robust connections that can convey content via unmatched rates. The new PSDM system is Conductive Film {a|an|one|the|particular|